Mining Technology

Well ahead in underground mining

Eickhoff and the mining industry are inextricably linked. Components for underground use were among the first products of the company – and when Europe‘s first bar coal cutter was put into operation as a complete Eickhoff system as early as in 1914, a virtually unique success story started in underground mining. So it did not take long until Eickhoff mining machines were exported to all parts of the world, with an initial bulk order coming in from abroad in 1926. And it was in the middle of the 70’s that Eickhoff was the first Western supplier to be approved for mining equipment in China.

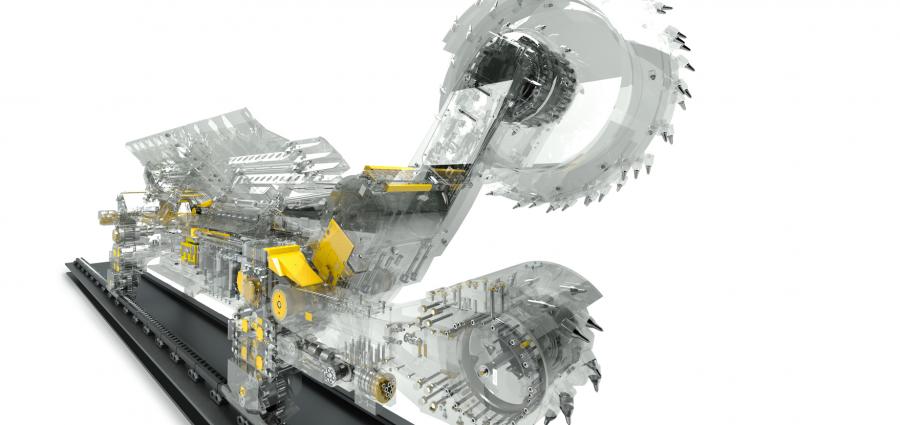

From the very beginning, the Eickhoff engineers have dedicated their extensive experience and deep passion to the development of better and better machines with ever-increasing efficiency and reliability. By doing so, the limits of feasibility are often being redefined as is the case with the maximum cutting height of the shearer loaders: In 2001, the commissioning in South Africa and China of two shearer loaders designed for a cutting height of 5.5 m, was a world record. The year 2007 saw the initial operation of the Eickhoff SL 1000 – with a cutting height of as much as 6 m. Meanwhile, a shearer loader for 7.2 m is operating in China which is, of course, another world premiere. And very soon the Eickhoff SL 1000 for a cutting height of 8.6 m will be put into operation – yet another world record!

Eickhoff underground mining machines are known for their robust and reliable design and excel by their quality in day-to-day operation.

They are more powerful, offer higher availability rates and have a significantly longer life than competing products. All that translates into production records.

Apart from high reliability it is the continuous innovations which contribute to the non-stop setting of new production records and make the Eickhoff shearer loaders more and more efficient. The EiComatik system, for example, originally controlled the shearer loader speed in relation to the cutter motor load. EiControl initiated the start of automated cutting. And EiCotrack, by the way, is an Eickhoff-invented chainless haulage system for shearer loaders which is meanwhile international standard and comes in multiple versions and designs. These further developments have been, and are, regular award winners.