CHAIN CONVEYOR GEARBOXES

Building gearboxes has always been one of Eickhoff's core competencies. Whether in the icy heights of the numerous offshore wind turbines or under the tropical conditions in 1000 m deep underground mines - Eickhoff gearboxes steadily operate with high precision and are capable of withstanding extreme loads.

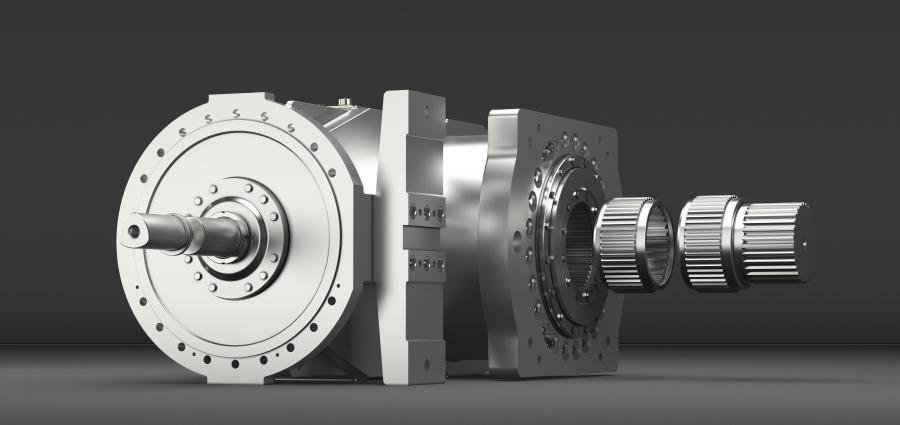

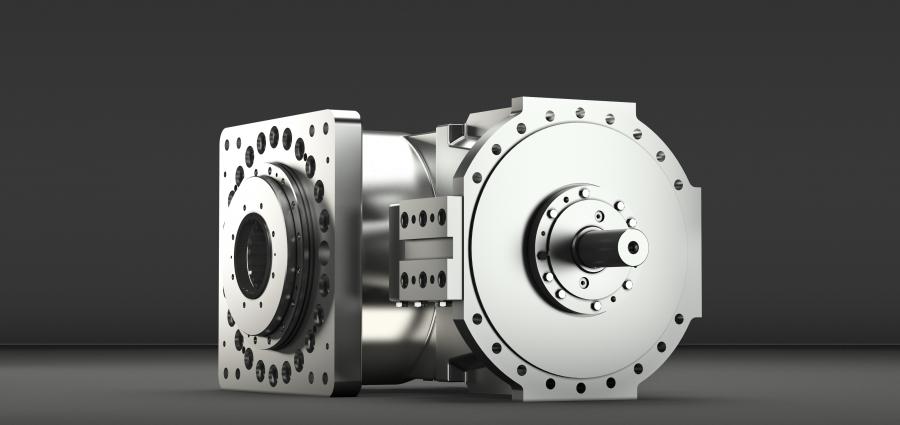

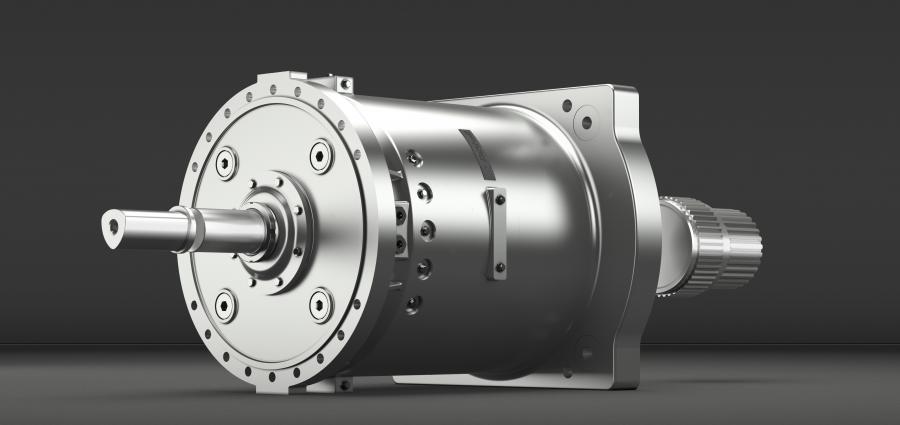

This is also true for the Eickhoff armoured flexible chain conveyor gearboxes of the EP and EKP series. They meet all the requirements with their double-stage planetary gearboxes or three-stage combinations of bevel wheel, spur wheel and single-stage planetary gearbox.

Eickhoff manufactures chain conveyor gearboxes up to the 65-series size for a maximum output torque of 650 kNm. Self-aligning sun gears ensure a uniform load distribution on the three planet wheels. A total of five different reduction ratios can be achieved by exchange of the first planetary gear stage of the EP series or a spur gear stage of the EKP series.

The gearboxes are extraordinarily compact. Planetary gearboxes manufactured by Eickhoff are up to 50% smaller, 15% lighter and 37% shorter than conventional gearboxes. The resultant cost benefits are directly passed on to the customers. Another special advantage of the Eickhoff gearboxes is the integrated oil cooler which ensures an optimal heat exchange within the entire housing. All gearboxes are supplied as standard with integrated cooling water chambers for cooling the high-speed components.

The output end connection flange of the gearboxes is made of high quality nodular cast iron from Eickhoff's in-house foundry and specifically designed for the extreme and alternating loads on the chain conveyor. A taper bush connects the planet carrier of the gearbox to the drive shaft of the conveyor. If necessary, the bush can be replaced with little effort, without having to dismantle the gearbox.

Exchangeable input and output shafts ensure smooth compatibility with the most diverse technical environments. Optimal lubrication is ensured even in high inclined applications by a splash lubrication system. A broad range of accessories for monitoring the cooling and lubrication systems is also available and rounds off the product portfolio.